Conventional pallet racking system is the best solution for warehouses, stores Where it is necessary to keep a wide range of articles in pallets. The wide range of profiles and accessories provides optimal adaptation to each load And height requirement. The layout and height of the racking are determined by the characteristics of the forklifts/ stackers, pallets to be stored and the dimensions of the premises. These pallet racking systems are used for non palletized loads also which is handled manually. The racking systems can be provided with sectional shelves/chipboard/wiremesh grating for storage of goods.

CONVENTIONAL PALLET RACKING SYSTEMS:

/HEAVY%20DUTY%20RACKS/Selective%20pallet%20racking%20(3).jpg)

DRIVE IN PALLET RACKING:

The storage concept consists of a set of racking units which form an internal lane with support rails for the pallets. The forklift/Stacker enters the lane with the load elevated above the support rail that it will be placed upon. Guide rails facilitates forklift/Stacker manoeuvres, thereby aiding movement and minimizing possibility of accidental damage.

RADIO SHUTTLE PALLET RACKING:

.jpg)

This is a storage system for high density pallets which facilitates the loading and unloading of goods from an electric cart called the Radio-Shuttle. Forklift/ Stacker lift the load on to the Radio-Shuttle which moves along the rails to place it on Its location. Different sensors control the movement of stored cargo with high accuracy. The operator guides all the movement of the Radio-Shuttle through a remote control Which transfer commands. One transmitter can command several units at once.

GRAVITY FLOW PALLET RACKING:

Gravity flow pallet racking features roller tracks on sloped lane to allow the pallets to slide over them. The pallets are placed at the highest part of the rolling section which then move by the force of gravity at a controlled speed to the other end, ready to be removed.

LONG SPAN SHELVING:

The Long Span Shelving is designed where the merchandise is not transported or delivered in a pallet, but deposited and withdrawn manually from the shelving. This system is ideal for products with a high number of references, when the quantities are minimal or variable and when the rotation is only partial.

MULTI TIER STORAGE SYSTEM:

This is to make maximum use of the available space inside tall warehouses/ shop floor. Multi tier means each level is a mirror image of the ground floor lay out, walkways are only fitted between the racks using the racking posts to provide the strength and rigidity of installation. This makes the system very cost effective. As per the storage requirements and applications multi tier systems are made with slotted angles and shelves for small parts/ bins and for heavier goods these can be made with upright frames and load beams along with deck panels.

MEZZANINE FLOORING:

The installation of a mezzanine is the ideal solution in order to take full advantage of the surface area of industrial/warehouse premises or any other premises, since if the height of a building can be put to full use the investment in land will be reduced. These mezzanine floors are easily dismountable, which means that all elements are recoverable, and their structure, dimensions and location can easily be modified.

FIFO RACKS:

FIFO storage for picking stores the goods on roller platforms which are designed to a sloping lane to allow items to move by the force of gravity. The goods are fed in and slide down by the force of gravity to the other end which leads to the exit aisle. The goods slide down roller lanes which guarantee perfect product turnover, prevent interference in the replenishment of stock, and increase the speed of order preparation.

MOBILE COMPACTOR SYSTEM:

Mobile compactor system is a compact storage system comprising of shelving mounted on mobile bases which slides along rails. This means that all but one of the aisles between the shelving units are eliminated and the modules are moved to access the required aisle. This system optimizes available space, guaranteeing that archived material is kept in order, clean and safe. This is a compact storage system, therefore storage space can be doubled, or the amount of space required reduced.

SLOTTED ANGLE RACKS AND PIGEON HOLE RACKS:

These racks provides the best solution for a broad range of storage applications that conform with manually handled light and medium loads. Slotted Angle Racks covers all storage requirements, ranging from totally planned requirements to the most immediate. The system is ideal for manual storage of light loads and even relatively heavy ones.

TWO-TIER STORAGE SYSTEM:

These are perfect to store segregate, identify & retrieve on infinite range of small and medium sized items in any quantity. This system can be designed to meet your changing needs.

Two-tier storage system is first choice for companies storage & distributing small & medium sized parts orders.

It's design flexibility means compact, efficient storage, easily accessible loads and the shortest possible picking routes.

CABLE REEL RACKS:

These are mainly for storage of Cable Reels, Cable Drums and various types of similar products. Cable drum stands for storage and unwinding cables directly from the storage position of rack. These bolted racks can be adapted flexibility to the widest variety of different requirements.

CANTILEVER RACKS:

A highly simple and rugged system designed for storage of long loads. The height and weight of the product determine the criteria of the Cantilever racking between light duty and heavy duty. Both offer the possibility of locating storage levels on one side or both sides of the structure.

ROLL OUT SHEET STORAGE RACKS:

These racks make sheet metal much easier to handle for convenient loading and retrieving with a crane, Overhead hoist, forklift or stacker. And can handle very heavy loads in a tight space. Standard capacities ranges from 1500kgs per shelf can be expanded to 5000kgs in certain sizes and configurations.

WORK STATION:

These are industrial workbenches. They are built for rugged durability and stand up to the harshest work environment. With a flexible selection of standard components and cost effective custom configurations, our industrial workbenches are ready to take on tough jobs.

TOOL CABINETS:

Tool Cabinets are versatile and flexible storage cabinets are an ideal fit for wide range of workspace and storage needs from manufacturing, Tool room, R & D to maintenance departments to accommodate items in a variety of sizes and shapes stored in a convenient and logical manner.

PERFO TOOL CUPBOARD:

The perfo. tool cupboard is a simple, adaptable space saving storage system for tools, small parts and consumables. Ideal for creating an efficient working environment for storage solutions via a wide range of tool holders and small parts bins, allows you to create a unique system which maximizes use of your space.

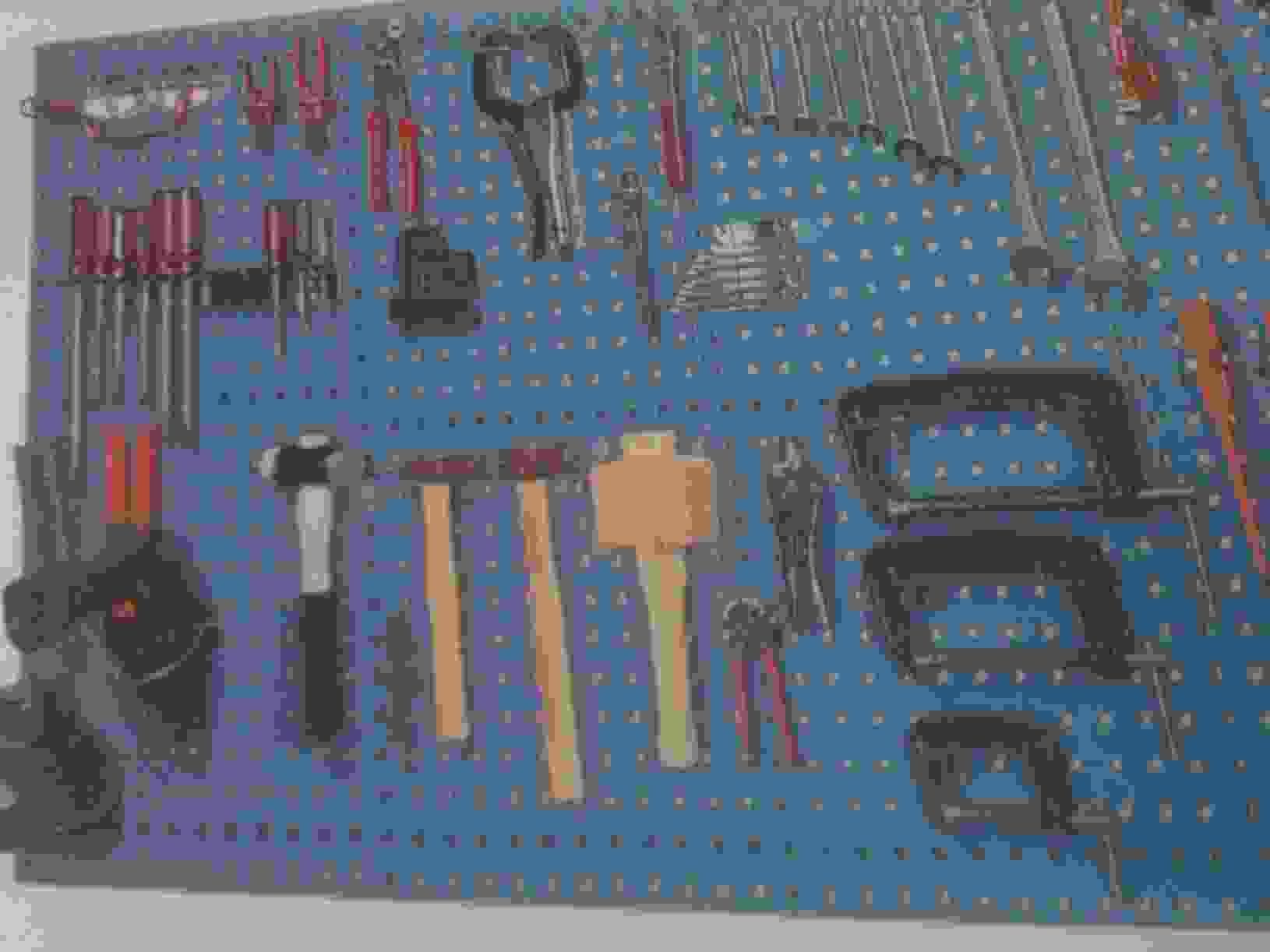

PERFO TOOL BOARD:

Perfect for storing your tools safely and efficiently. Perforated panels offereasy access to your whole collection as well as a clear visual reference to help you keep your inventory together and identify missing tools on perfo tool board. These are available with wide range of accessories to store different types of tools on perfo tool board.

Products

- PALLET RACKING SYSTEMS

- DRIVE IN PALLET RACKING

- DRIVE IN WITH RADIO PALLET SHUTTLE

- GRAVITY FLOW PALLET RACKS

- LONG SPAN SHELVING

- MULTI TIER STORAGE SYSTEM

- MEZZANINE FLOORING

- FIFO RACKS

- MOBILE COMPACTOR SYSTEM

- SLOTTED ANGLE & PIGEON RACKS

- TWO TIER STORAGE SYSTEM

- CABLE REEL RACKS

- CANTILEVER RACKS

- ROLL OUT SHEET

- WORK STATION

- WORK BENCH

- TOOL CABINETS

- PERFO TOOL CUPBOARD

- PERFO TOOL BOARD

- LOUVRE PANELS